Specifications

| Application | Architectural, residential, commercial and industrial panels. |

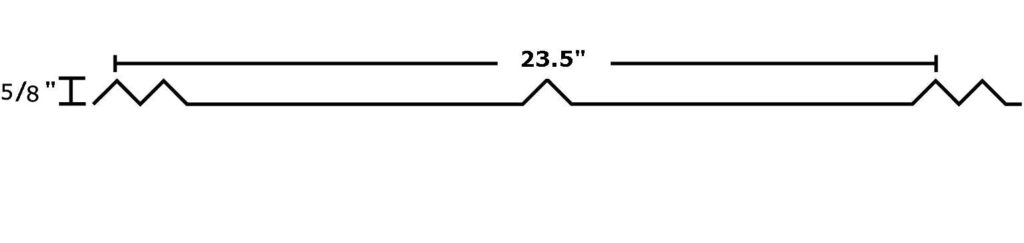

| Coverage | 23.5″ panel coverage, with a 5/8″ seam height on Standard profile. 1/2″ seam height on Double and Multi Striated. |

| Minimum Slope | Recommended slope 2/12 or greater. |

| Substrate | Recommended substrate 1/2″ – 5/8” plywood with a minimum 30 lb. underlayment. |

| Length | Panels are continuous lengths from eave to ridge. |

| Fastening System | Exposed fastening system. Recommended that panels are fastened to substrate at center rib and inside rib of side lap, with a maximum spacing of 16″ o/c. |

| Fasteners | 1-1/2″ self-sealing neoprene washer screws. |

| Materials | Panels are fabricated from 26 gauge or 24 gauge Galvalume*. |

| Coatings & Finishes | 26 gauge pre-painted Galvalume* panels are available in a variety of colors. 24 gauge pre-painted Galvalume* panels are available in a variety of colors and coated with a full-strength Kynar 500 finish. |

| Warranty | 20, 25, and 35 year manufacturer warranties available. |

| Approvals & Testing | Florida Building Code and Miami-Dade HVHZ product approvals, TAS 125 (UL-580 uplift resistance test), TAS 100-95 (wind driven rain test), Class A Fire Rating (UL-790), Quality Assurance Program. |

Additional Panel Information

- Panels are also available in Aluminum and 16 oz Copper.

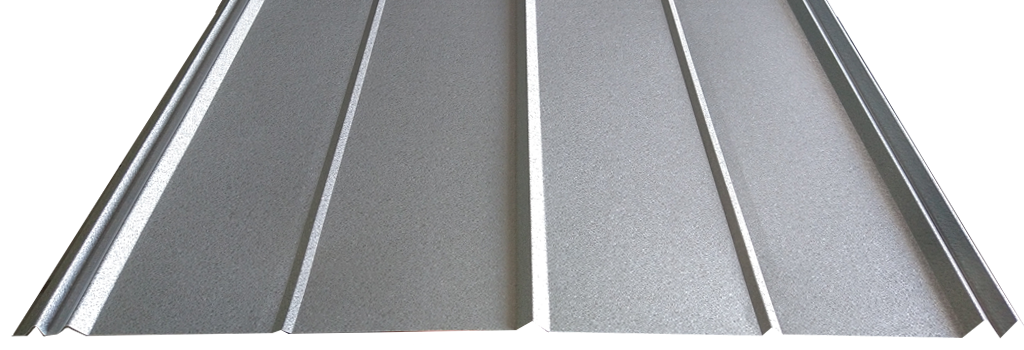

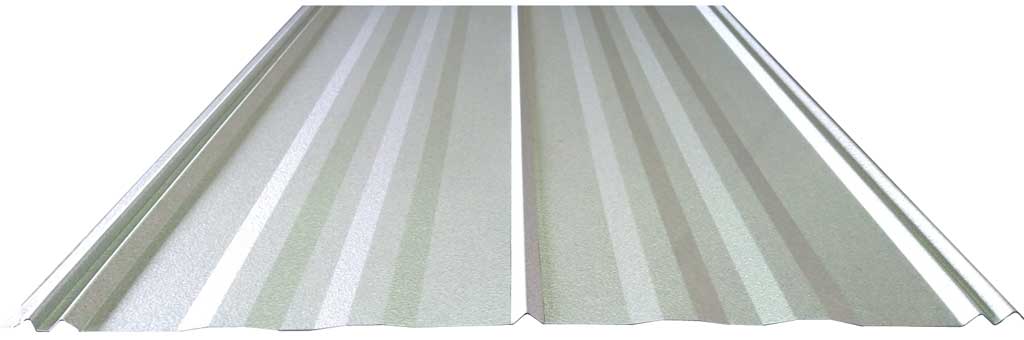

- Available in Standard, Double or Multi-striated panels.

- All flashings and accessories are fabricated from the same coil stock as the panels.

- 5-V orders are all-inclusive: panels, clips, screws, and all flashings are incorporated into one per square price.

* Galvalume uses an aluminum (55%) – zinc (45%) alloy coating that offers greater corrosive resistance, higher temperature oxidation resistance, and higher heat reflectivity than standard galvanized steel.

† Kynar 500 is a premium fluorocarbon coating, produced with full strength Kynar 500 resin. This affords maximum exterior durability due to its outstanding resistance to ultraviolet radiation. These are the highest quality finishes available.