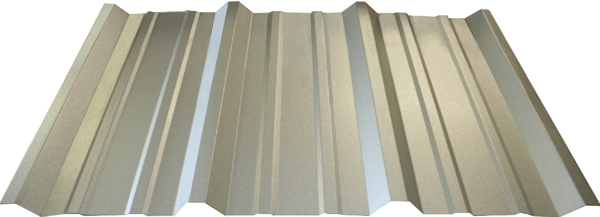

Specifications

| Application | Residential, Commercial, Industrial, and Agricultural panels. Used for wall and roof applications. |

| Coverage | 36” panel coverage, with a 1-1/4” seam height seam height. |

| Minimum Slope | Recommended slope 2/12 or greater. |

| Substrate | Non-Structural: 1/2”-5/8” plywood with a 30 lb. felt moisture barrier underlayment. Structural: Minimum 16 gauge steel purlin / girt |

| Length | Panels are continuous lengths from eave to ridge. |

| Fastening System | Exposed fastening system. Recommended that panels are fastened to substrate according to manufacturer specifications. Non-Structural (maximum): Field 16” o/c / Eaves 6” o/c / Gable ends 8” o/c. |

| Fasteners | Self-sealing neoprene washer screws (refer to manufacturer’s specifications) |

| Materials | Panels are fabricated from 26 gauge or 24 gauge Galvalume*. Also available in aluminum and copper. |

| Coatings & Finishes | 26 gauge pre-painted Galvalume* panels are available in a variety of colors. 24 gauge pre-painted Galvalume* panels are available in a variety of colors and coated with a full-strength Kynar 500 finish. |

| Warranty | 25, and 35 year manufacturer warranties available. |

| Approvals & Testing | Florida Building Code and Miami-Dade HVHZ product approvals, TAS 125 (UL-580 uplift resistance test), TAS 100-95 (wind driven rain test), Class A Fire Rating (UL-790), Quality Assurance Program, ASTM E 1592-01. |

Additional Panel Information

- Panels are also available in Aluminum and Copper.

- All flashings and accessories are fabricated from the same coil stock as the panels.

* Galvalume sheet uses an aluminum (55%) – zinc (45%) alloy coating that offers greater corrosive resistance, higher temperature oxidation resistance, and higher heat reflectivity than standard galvanized steel.

† Kynar 500 is a premium fluorocarbon coating, produced with full strength Kynar 500 resin. This affords maximum exterior durability due to its outstanding resistance to ultraviolet radiation. These are the highest quality finishes available.